Troubleshooting tips for the solar Off-Grid community, to understand common DC compressor error messages for a DC refrigerator or freezer to resume normal operation

For Off-Grid customers, it is critical to be informed to realize optimum equipment performance and achieve the longest autonomy possible. When equipment is not working as designed, trouble shooting is the best way to get the system back up and running quickly. When it comes to an interruption of performance for a DC refrigeration appliance, Phocos shares insights to support you with troubleshooting tips.

Quality DC refrigerators and DC freezers will have a red LED connected to the Electronic Control Unit (ECU) of the DC compressor to help consumers determine causes of failure. The red LED will flash between 1-6 times, pause for a few seconds, then repeat. If a DC refrigerator or DC freezer does not have a red LED, when problems arise contact the manufacturer for instructions.

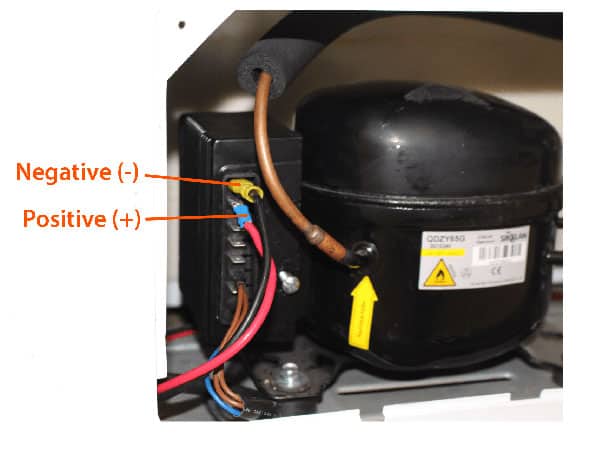

Most DC compressor fault errors are caused by low voltage that doesn’t cut out. Meaning the battery voltage is low, but not low enough to hit 9.6 Vdc, which causes an automated low voltage disconnect, protecting the DC compressor and ECU, shutting down the refrigeration unit. It is important to note, the DC appliance is not typically the root cause of the error. Often these challenges are caused by one of the following: poor system design, faulty wiring, long wire runs, corroded connections, faulty breakers, or damaged, weak or old batteries. There will be multiple error messages noted on a compressor’s specification sheet. However, the most common issues for typical applications in the field are low voltage disconnect and over voltage failure (>35.1 Vdc will damage the ECU). When checking voltage, always check at the positive and negative terminals of the DC compressor ECU.

There are approximately 3-4 major companies in the DC compressor business today. For this industry insight article, we will use the example of a Sikelan DC compressor. Error codes on all DC compressors are similar, so use this as a guide. It is important to check the specifications for your compressor model to determine the correct values for each error code.

1. One Flash – Battery protection cut-out (most common)

- This condition is caused by low voltage or over voltage

- 12 Vdc example – Normal cut out battery voltage between 9.6 Vdc on the low end and 17 Vdc on the high end

- Note: The voltage at the ECU can be lower than the system voltage, and the voltage should be checked at the ECU

2. Two Flashes – External Fan: overcurrent cut-out, the fan load is more than one Amp, however this only happens if you have a fan connected to the ‘F’ terminal

- Note: Not used for normal applications, typically only used in DC vaccine type of refrigeration, not included with unit

3. Three Flashes – ECU general failure (most common) or motor start error (typically happens when the system is overloaded – i.e. high ambient, and a large mass of warm product all at one time).

4. Four Flashes – Minimum motor speed error

- If the unit is too heavily loaded, problems occur (motor runs slower and once below 1850 rpm will shut down)

5. Five Flashes – Thermal cut-out of ECU

- Rare with today’s refrigeration options. An external fan was designed to go on the ECU. If it gets too hot, it will specifically cool the ECU. Typically, not required even in the worst conditions. Greater than >75 degrees C (160 degrees F). In extremely hot conditions if air space guidelines are followed it is not common to reach these high temperatures.

6. Six Flashes – ECU hardware failure (abnormal parameters – not common).

Experiencing failures in the field can be frustrating. The first step to getting everything working properly, is to understand what is happening with the DC compressor. The ECU can only tell you why the compressor is not running. It cannot determine failures or conditions beyond the ECU and DC compressor. This is important to keep in mind while troubleshooting, especially if the rest of your solar Off-Grid system is running fine. If your DC refrigerator or DC freezer is the only device that is not operating properly, it is the best place to start to identify the issue quickly. Then you can work on solutions to resume normal operation.